precision aluminium castings made in India - full service from Munich/Germany

safe up to 35% (compared to production in Europe)

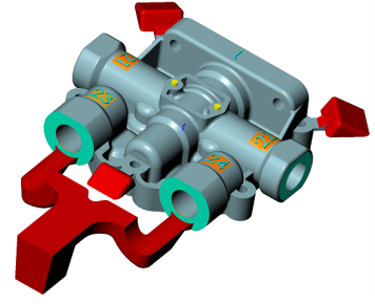

highly competitive aluminum and zinc alloy components through high pressure (HPDC), low pressure (LPDC) and gravity (GDC) die-casting processes

latest production equipment, smart process management and our long-term experience ensure highest quality

- HPDC lines, castings from 250g to 15kg

- LPDC lines, castings from 500g to 35kg

- GDC lines, castings from 50g to 75kg

cost efficient in-house tool designing and tool manufacturing

- rutinised planning and development of manufacturing processes and tooling designs

- validation of tooling design

- in-house pressure die-casting mold manufacturing for pressure die-casting up to 800t

- certified in-house testing lab

high/low pressure die-casting (HPDC/LPDC)

We have a wide range of fully automated casting machines from 60t to 800t capacity and can produce castings ranging in weight from 0,25kg to 15kg in PDC. Our PDC machines are equipped with automatic alloy ladling, automatic die spraying, and robotic casting extraction. To ensure consistent quality in the die casting process, we are using Visi–Trak® process monitoring equipment and software and tie-bar strain gages to measure the amount of strain placed on the tie bars of a die-casting machines.

gravity die-casting (GDC)

Our gravity die-casting fab includes horizontal clamping 2 in 1 GDC machines, tiltable gravity die-casting machines and stand-alone facilities. We can produce castings ranging in from 50g to 25kg in GDC.

machining and cleaning

- in-house CNC machinery for high-precision mechanical finishing (lathe and milling)

- ultrasonic cleaning

- assembly lines for component productions (e.g. medical equipment, aerospace)

testing and quality control

our certified testing lab is equipped with latest testing and QC technologies such as

- CMM machines

- UTM machines

- auto-gauging systems

- X-ray systems

- corrosion resistance testing chamber

- spectrometers

- leak-testing machines

surface treatment

we have the following processes in-house:

- vacuum impregnation

- polishing

- shot blasting

- anodizing

- chromating

- powder coating

Roots Cast Limited fab 1 in Coimbatore/India

our Munich-based service team is at your disposal and takes care of

- technical advice on all aspects of aluminium casting

- sales and customer service

- order management

- quality management

- logistics

- after sales service